Gallery

CityScapes Commercial Roofing LLC

Commercial Roof Project Portfolio

At CityScapes, our customers really are our number one priority. We value honest and open communication with our clients, recommendations for your best interests, and the highest quality work that will save you time and money down the line. Our work represents our passion for commercial roofs.

In this gallery you can see some of the great companies who trusted CityScapes with their commercial roofs. Be sure to also check out our before & after gallery to see stunning roof transformations.

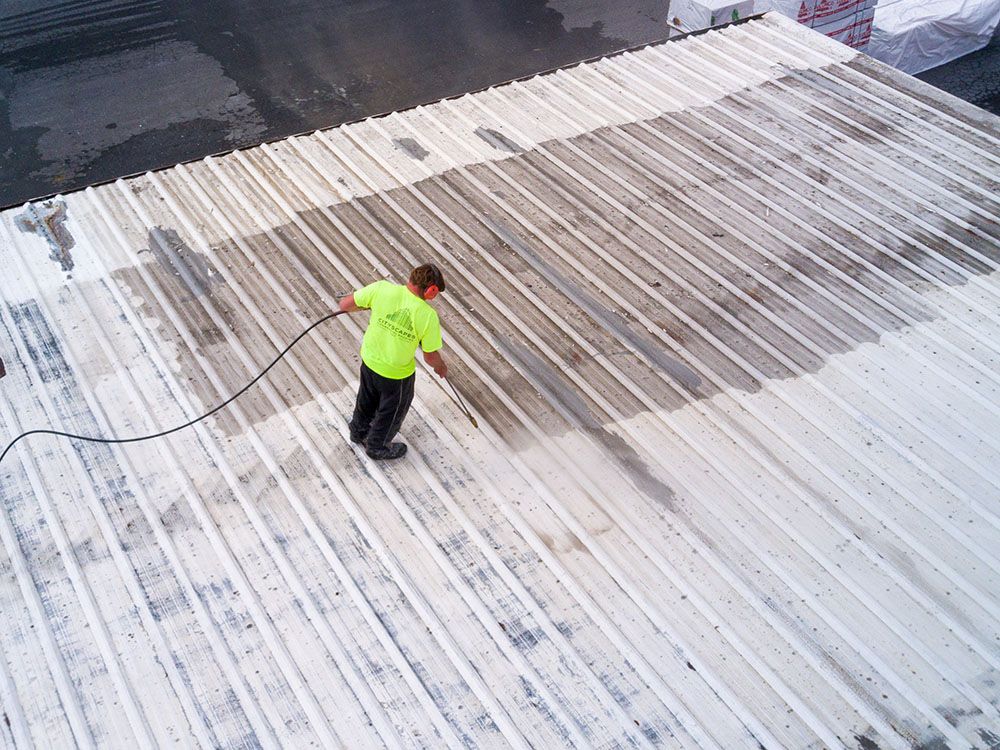

Metal Roof Restoration

See some of the recent metal roof restoration projects CityScapes has completed in the Mid-Atlantic region.

Abbottstown Industries

Abbottstown, PA

This little metal roof was leaking and rusting really bad at the seams and screws. By applying our Metal Roof Restoration System, we were able to stop all the leaks and provide the customer with an 18 year leak-free warranty.

Five Saints Distillery

Norristown, PA

This beautiful old historic building was originally a firehouse before Mr. George converted it into a distillery and bar. The metal roof had several layers of coatings on it prior, which we were able to remove with our pressure washer. After applying our system, the roof was totally leak free.

Groff Tractor & Equipment

Ephrata, PA

Even though we like all types of commercial roofing, Metal Restorations are some of our favorites. This 10,000 square foot metal roof was no exception. This project called for Encase Metal Primer, Benchmark acrylic base coat with embedded fabric on all seams, Kwik Kaulk elastomeric acrylic caulk compound on screw heads, and Puma XL polyurethane modified acrylic top coat on entire roof.

Whitley East

Leola, PA

This almost 60,000 sqft metal roof in Leola, PA had a lot of age and multiple layers of old coatings on it. With sandblasting and pressure washing, we were able to remove the old coatings, creating a clean, stable foundation for our metal roof restoration system. The building manager said that in addition to eliminating all the leaks, they noticed that the building stayed much cooler after we installed the white, Puma XL top coat!

Roof Replacement

When a roof is past its life expectancy, sometimes a replacement is necessary. See some of the

roof replacement projects we’ve completed in PA & NJ.

Amazing Kidz Daycare

Reading, PA

The existing roof was multiple layers of membrane, ranging for Modified Bitumen to EPDM (black rubber). Prior to installing our new system, we removed it all, including three layers of flashings on the perimeter wall. We also replaced some wood decking that was rotted.

Aras Fine Rug Cleaning

Malvern, PA

This was an old .75” Fiberboard and Modified Bitumen Roof. After removing that, we installed 5” of PolyIso Insulation with an R- Value of 28.5, prior to covering it with white TPO Membrane. This customer will be saving lots of money on future heating and cooling costs.

Dunkelberger's Sports Outfitters

Stroudsburg, PA

Two sections of this roof were in good enough shape that we were able to apply our Fabric Reinforced Coating System right on top of the existing EPDM (black rubber). The main section was saturated with water, so on that section we removed the existing roofing and insulation and installed a new PVC membrane system.

Hometown Farmers Market

Tamaqua, PA

This little roof was EPDM (black rubber) with no slope at all. After removing the existing insulation and membrane, we installed a tapered insulation system to create drainage, and white PVC Membrane. We were able to provide the customer with a 25 year warranty.

JM Lapp Plumbing and Heating

New Holland, PA

This roof had wood decking, 1” insulation, and EPDM membrane (black rubber). It was leaking in multiple area. We removed the EPDM, all areas of wet insulation, and replaced the wood decking where it was rotting. After adding an additional layer of 2” insulation, we installed new, white TPO membrane.

Kutztown Tavern

Kutztown, PA

This project consisted of removing the existing membrane and 3/4” insulation, and installing two layers of 1.5” Polyiso Insulation and white PVC membrane. We also installed walk pads around the roof units to protect the roof from foot traffic. By adding 3” of insulation, we increased the R-Value on this roof to about 17.1, making it much more energy efficient. The free lunch everyday, from the amazing chefs at Kutztown Tavern, was a nice bonus. Best food ever!

Theodore E. Dando D.M.D

Hamburg, PA

This dentist’s office roof was completely flat, and looked like a lake every time it rained. After removing the existing EPDM (black rubber) and insulation, we installed a tapered insulation system and white PVC membrane. The peak and slight slope to the edges, which we created with our tapered insulation, completely took care of the ponding issues. We also installed new 7” commercial box gutters on two sides of the building.

Membrane Restoration System

In some situations, you can restore your commercial roof instead of replacing it. See some of our recent

roof restoration projects.

Amazing Kidz Daycare

Reading, PA

For Amazing Kidz Daycare’s Sixth Street location, we had to go in a back alley that was barely wide enough for our coatings trailer to fit through. We used a Rapid Roof III acrylic base coat and 5″ Spunflex Fabric on the seams, and a White Rapid Roof III top coat on the entire roof.

Bonn Place Brewing Company

Bethlehem, PA

The owner of Bonn Place Brewing recently purchased this building, to expand his already successful beer brewing business. He preferred that we don’t tear off the existing roof, and because there was only one layer of roofing on top of the concrete decking, we didn’t need to. We simply went over top of the existing roofing with one layer of .5” high density cover board and PVC Membrane.

Dairy Advantage

New Holland, PA

This roof was in decent shape, however there were no crickets at the bottom edge to divert the water to the drains. Because of that, the roof had started to leak in that area. After installing tapered insulation crickets, we applied base coat and fabric to the membrane seams on the entire roof, and then top coated it with our white PUMA XL acrylic coating. That allowed us to warranty this roof for 18 years.

RV Industries

Honey Brook, PA

Part of this roof had fully adhered EPDM (black rubber) that wasn’t in terrible shape, and part roof was ballasted EPDM. On the ballasted area, we removed the rocks and the membrane, added one layer of 2” ISO insulation over top of the existing 1.5” layer, and installed new PVC Membrane. The following year we came back and installed our Membrane Restoration System on the area that had fully adhered EPDM.

Spray Polyurethane Foam

Here are some recent projects that utilize

spray polyurethane foam for a waterproof, energy-efficient roof coating system.

Apartment Complex

Stroudsburg, PA

This apartment building roof had a lot of leaks. Thankfully it was in good enough shape that we didn’t have to tear it off. After cleaning it, we applied 1.5” of Spray Polyurethane Foam to the roof, prior to coating it. The foam added significant R-Value to the roof, and at the same time allowed us to correct some of the ponding issues on the roof.

Goldstar Properties

Clinton, NJ

This roof already had two layers of roofing on it, and the owner preferred not to do a complete replacement. Our solution was to simply spray 1.25” of Spray Polyurethane Foam and two coats of acrylic coatings right on top of the existing roll roofing. Spray foam adds minimal weight to the roof, which makes it a great option when adding another layer of membrane roofing is not an option.

Fabric Reinforced Coating System

For these projects in PA & NJ, we used a

fabric-reinforced coating system to form a rugged, waterproof membrane on the roof.

TrimMaster

Temple, PA

This 40,000 square foot EPDM roof was not in bad shape, however it did have minimal leaks, and the customer wanted to extend the life of the roof and make it more energy efficient. After installing our fully fabric reinforced white coating system, we were able to provide the customer with an 18 year leak-free warranty.

Warren Animal Hospital

Phillipsburg, NJ

We completed this little fabric reinforced coatings project late in the fall, which was a bit of a challenge with all the leaves coming off the trees and landing on the roof. Thankfully, the project was a success and looked great when we were finished. The customer told me later that by changing the roof from black to white, parts of the interior that they were having trouble cooling in the summer was no longer a problem.

Share On: